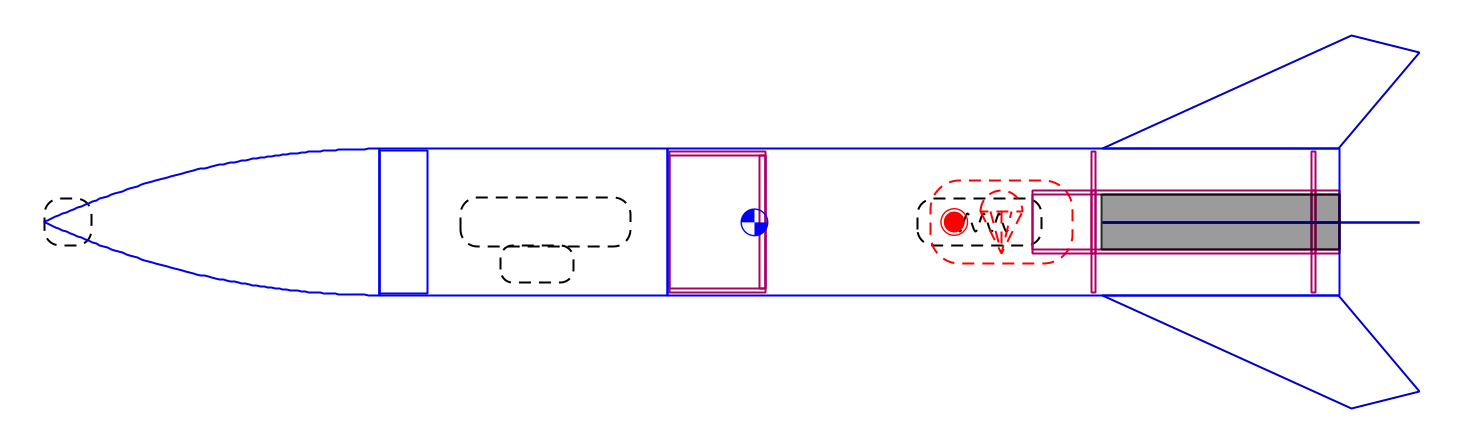

AX-1.1: DEMONstrator Rocket

This is the 3D-printed build acting as a proof of concept for innovative fastening and mounting methods, achieved with CAD, 3D printing, and filament experimentation under Arkane Works. Developed a modular 3D-printed rocket platform for parallel Level 1/2 missions using PETG-CF filament for the body tube and PPA-CF for the motor mount, optimizing strength-to-weight ratio and heat resistance.